How Much Does Anodising Cost?

Introduction

In this post, we look to answer the common question, How much does Anodising cost? We share with you some of the variables that will affect the cost of anodising, and explain how using one of our approved suppliers reduces your purchasing risks and ensures the delivery of quality components.

What is Anodising?

Anodising is an electrolytic process, where aluminium components are dipped into a sulphuric or chromic acid solution, which produces a thick oxide coating on the surface of the component.

The thickness of the oxide layer can range from 5 to 100 microns, depending on customer requirements. Anodising is normally used to give parts a colourful surface for decorative purposes, or to improve wear and corrosion resistance.

There are several different types of anodising, which include Natural Anodising, Colour Anodising and Hard Anodising.

Advantages of using Parallel Precision

All of our suppliers are continually audited to our strict criteria, which includes value, quality and responsiveness. These features, and more, are documented on our comprehensive 43 question quality survey.

We use ISO 9001 : 2015 approved suppliers where possible, which means our suppliers have documented procedures for preventing, identifying and dispositioning nonconforming parts. This means that quality is monitored at each stage of the manufacturing process, and in the unlikely event that parts are out-of-spec, these are identified, segregated, and prevented from being sent out to the customer without the customers approval. All non-conforming parts are then subject to an internal investigation to discover the root cause of the failure to prevent future occurrences.

Parallel Precision gives you peace of mind that when you use us to get your parts Anodised, they are sent to a supplier that consistently delivers great results. The hard work in trying to find a quality Anodiser and auditing their internal quality processes has already been done for you.

Our customers rate us Excellent or 5/5 ***** when asked:

Including outsourced processes, how much do you trust us to deliver as promised?”

The Cost of Anodising

If you find yourself asking “How much does Anodising cost?”, the three main variables that need to be identified before the cost can be determined are:

- Which Anodising process do you require?

- How many components are you Anodising?

- What are the dimensions of your components?

Once these have been established, an estimate on the cost of anodising can be determined. There are however several other factors that could increase or decrease the Anodising costs that should not be overlooked. These include; requested lead time, a minimum order quantity set by certain suppliers and any pre-processing requirements such as bead blasting.

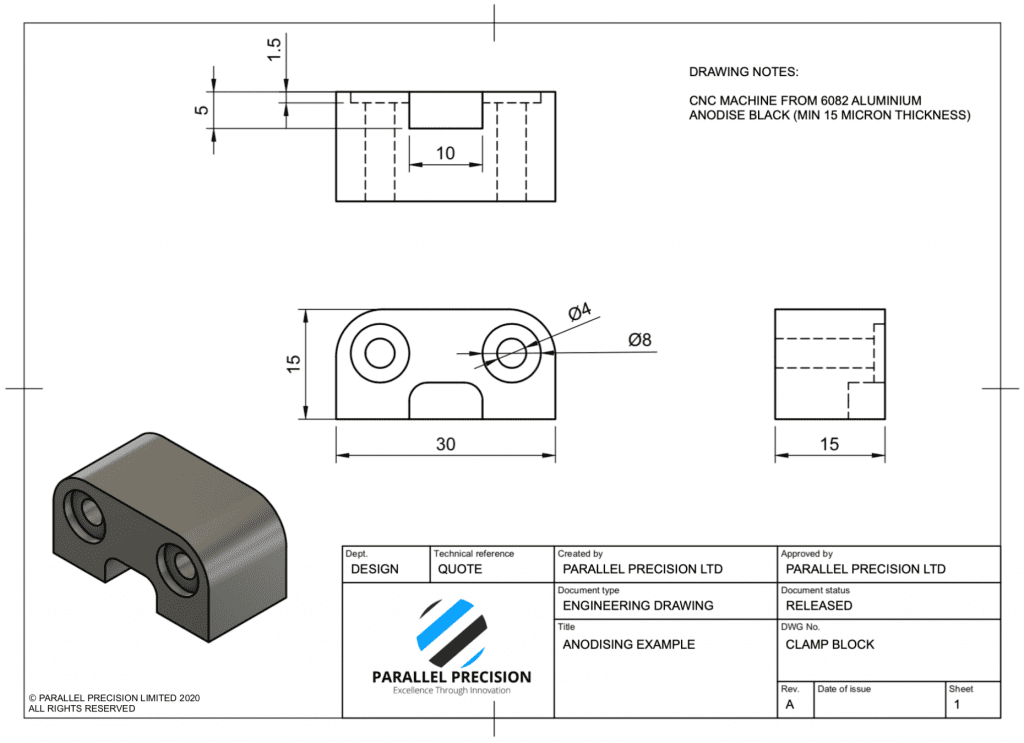

To offer an example of the cost of Anodising, we have created a simple aluminium example component with the requirement is for black anodising with a minimum thickness of 15 microns. These anodising costs are based on the quantity and lead times shown below.

| Quantity | Lead Time | Anodising Cost (Per Item) |

|---|---|---|

| 1-off | 6-7 Business Days | £120 + VAT |

| 2-off | 6-7 Business Days | £60 + VAT |

| 5-off | 6-7 Business Days | £24 + VAT |

| 10-off | 6-7 Business Days | £12 + VAT |

| 20-off | 6-7 Business Days | £10 + VAT |

| 50-off | 6-7 Business Days | £4 + VAT |

| 100-off | 6-7 Business Days | £2.80 + VAT |

| 200-off | 6-7 Business Days | £2.50 + VAT |

| 500-off | 7-10 Business Days | £2.20 + VAT |

| 1,000-off | 7-10 Business Days | £1.95 + VAT |

The sample component in which this prices were based on can be seen below:

Lead Time

The average lead time for a batch of anodised components to be processed is around 8 business days. This can vary depending on the workload of the Anodising supplier at the time.

If you parts are required more urgently, Parallel Precision works with two Anodising suppliers that offer a 48 hour turnaround for a 50% surcharge. This depends upon the requested Anodising process, order quantity, part dimensions and part complexity, but in most cases, the 48 hour turnaround is achievable. If you wish to benefit from this rapid turnaround service, please get in touch.

Best Price

We dont offer standalone anodising service, however, if you have requirements for CNC Machined aluminium components that also need anodising, send your requirements to us today to receive an accurate quotation. If you have requirements for anodising and let us know you have read this blog post we will give you 10% off the cost of anodising!

Conclusion

After all the variables are taken into consideration, we reach our conclusion

The typical cost of anodising small sized components can cost anywhere between £120 to just under £2.00 per item, depending on the size of the part, the anticipated order quantity and the chosen Anodising process.

If the price per item is lower than this, your chosen Anodising service supplier likely doesnt have a rigorous procedure in place to monitor the consistency of their processes, meaning the quality of your finished components is likely at risk.

As mentioned in the article above, we continuously audit our supply chain to make sure your components are delivered exactly as you would expect them. We believe value is more important than cost, so dont sacrifice quality for cost and place your next order of Anodised components though Parallel Precision. If this articled helped, or you think you can benefit from our manufacturing services, feel free to contact us at your earliest convenience.

Related articles

New CNC Machine

At Parallel Precision, we recently invested in a new VMC. The addition of a new Hurco VM10i gives our manufacturing department even more CNC Milling Capacity. The purpose of this new 3 axis machine is

CNC Milling Capacity

Act quick! For a short period of time, we have capacity to offer rapid turnaround for all CNC Milled components. This offer works on a strictly first come, first served basis

What is a CNC Mill?

Learn more about CNC machining, a subtractive manufacturing method used to create a variety of complex shapes in a broad range of materials from plastics to hard metals